Request Formal Quote

Fill out the form below to receive a quote on this machine. Once the form is filled out, you will be able to see all pricing throughout our website.

Bystronic Bystar 3015-3 4000 Watt Laser w/ Rotary Axis

Stock #: CL-B-171036

$42,000.00

Request Formal Quote

Fill out the form below to receive a quote on this machine. Once the form is filled out, you will be able to see all pricing throughout our website.

Product Description

General Info:

Stock #: CL-B-171036

Location: Cartersville, GA 30121

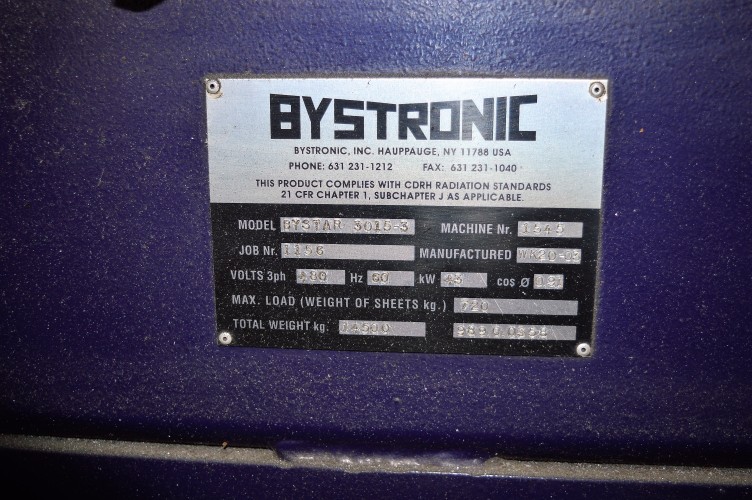

Brand: Bystronic

Model: Bystar 3015-3

Serial: 1545

Year: 2003

Approx. Shipping Weight: 38,000 Lbs.

Loading Fee: Rigging Required

Specifications:

Nominal Sheet Size: X-120″ Y-60″

Cutting Range: X-120″, Y-60″ Z-6.70″

Maximum Positioning Speed (Axis Parallel): X & Y 3,150 in./min.

Maximum Positioning Speed (Simultaneous): 4,450 in./min.

Maximum Axis Acceleration: 177 in./s2

Positioning Accuracy: Pa* +/- 0.004″

Repeat Ability: * +/- 0.002″

Edge Detection Precision: +/- 0.020″

Maximum Work Piece Weight: 1,962 lbs.

Max. Sheet Thickness (Mild Steel): 1″

Max. Sheet Thickness (Stainless Steel): 0.75″

Max. Sheet Thickness (Aluminum): 0.50″

Equipped With:

Bystronic Windows NT CNC Controller, Automatic Shuttle Tables, Chiller, Movable Scrap Trays, Automatic Sheet Edge Sensor, Cut Control, Bypos Auto Focus, Cross Jet Nozzle, Back Reflection Isolation CPP, 5.0″ and 7.5″ Capacities Height Sensing Cutting Heads w/ Lens, Nozzle Alignment Tool, Dust Collection System. PI Parts Kit Rotary Axis and Bystronic Byloader

Additional Info:

Replacement Parts: Total cost (parts, travel, labor) January, 2016 thru 8/31/2017 $78,506.11. Blower replaced in January, 2017. New Cutting Head 7.5″ February, 2017. Replaced Glass Tubes and O-rings March, 2017. Total running time: 61,520 Hrs. Total beam on time 29,612 hrs. Please note, this number will rise as it is still in use for production. Machine is under power and can be demoed upon request.

This machine is being sold from our client’s facility and is being sold AS-IS (Not covered under the MDNA Return Privilege). We always recommend machine be inspected in person to verify condition.

Related Listings

Is this not quite what you're looking for?

If we don't have what you're looking for in stock, we'll see if we can find it for you - fill out the form below and we’ll be in touch.

Do You Have any Surplus Machinery You Want to Sell?

We buy single machines up to complete plants.